A recyclable biomass film that can adapt to day and night energy saving

- Share

- publisher

- hoey

- Issue Time

- Aug 16,2024

Summary

This study presents a recyclable biomass film with dual cooling and heating sides, enhancing building energy efficiency with high reflectance and durability.

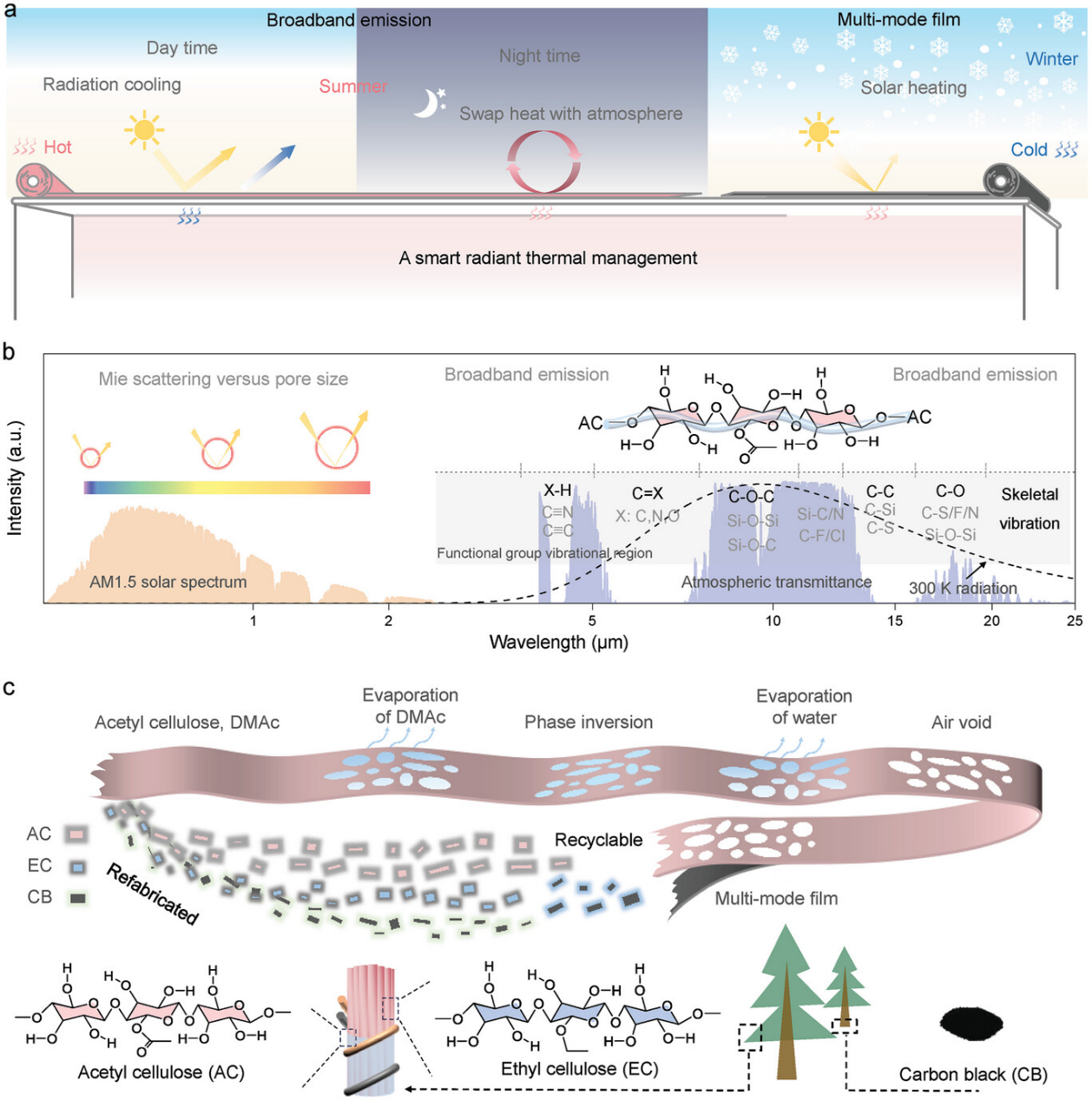

Introduction to Building Energy Use

Buildings account for over 40% of global energy consumption, with nearly half used for space heating and cooling. By 2050, cooling demand is expected to increase by 83%, and heating demand by 79%. Reducing the carbon footprint associated with building energy use is crucial for sustainability. Employing green and sustainable energy sources and developing new technologies can curb energy use and greenhouse gas emissions. To achieve this, it is important to leverage natural radiation sources, such as outer space (3K) and the sun (6000K). For daytime radiative cooling, buildings must have high reflectance (0.3-2.5µm) and high emissivity (8-13µm). Conversely, for radiative heating, buildings must have high absorbance (0.3-2.5µm). Janus-type materials designed for seasonally adaptive radiative heat regulation offer a promising solution.

Introduction to the Intelligent Biomass Film

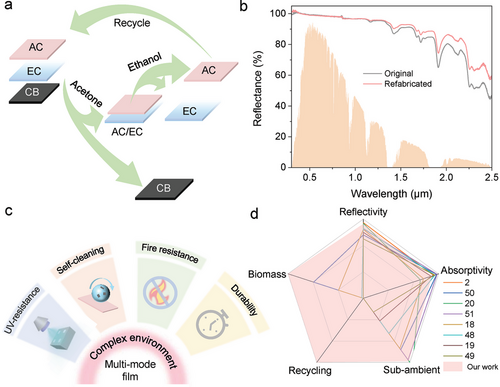

Recently, Professor Haibo Zhao’s team from Sichuan University reported a recyclable, adaptive biomass film that saves energy year-round. This film uses porous acetylated cellulose (AC) as the cooling side matrix, achieving efficient radiative cooling (8.5°C reduction) during hot days and minimizing excessive cooling (2.5°C reduction) during cold nights. High solar reflectance (96.3%) and broad-spectrum infrared emission (95.4%) enhance atmospheric thermal regulation. The back side coated with carbon black (CB) shows excellent solar heating (20.9°C increase), allowing easy switching between cooling and heating by flipping the film. Additionally, the film uses solvent-reacted ethyl cellulose (EC) for adhesion, ensuring durability and full recyclability. This film offers UV resistance, self-cleaning, durability, and intelligent thermal management, presenting new ideas for advanced radiative thermal management materials adaptable to day/night and summer/winter conditions.

The related work was published in Advanced Functional Materials under the title “An Intelligent, Recyclable, Biomass Film for Adaptive Day-Night and Year-Round Energy Savings”.

Preparation and Characterization of the Film

The preparation of the intelligent film involves dissolving AC powder in DMAc (dimethylacetamide), coating it on glass, and drying to remove DMAc. The material is then immersed in a condensation bath, inducing phase separation through strong interactions between DMAc and water, forming micro-nano porous structures. CB and EC are sprayed onto one side of the AC. The resulting multimodal film exhibits different visual characteristics on its two sides. The cooling side, observed under SEM, shows a porous layered structure with nanoparticle spheres averaging 0.15 to 2.25µm, meeting effective solar radiation reflection standards. The heating side is coated with CB and has an average thickness of 2µm, with the total film thickness reaching 300µm. The cooling side has a reflectance of up to 96.3%, and the heating side has an absorbance of 91.1%, demonstrating excellent adaptability.

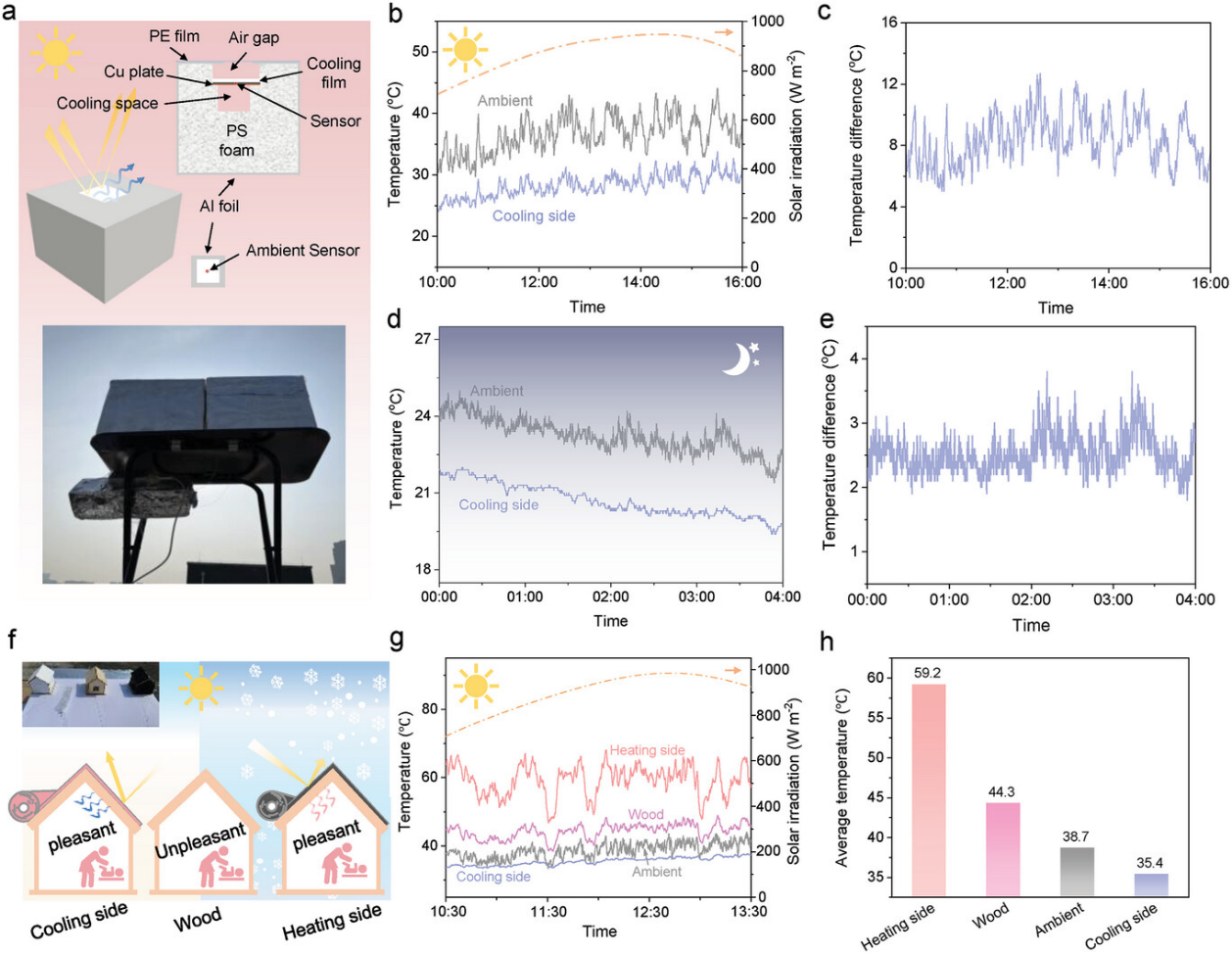

Smart Radiative Thermal Management

The film's real-time temperature and ambient temperature were measured under various conditions. On sunny summer days with an average solar radiation power of 873 W m−2, the cooling side reduced the sub-environmental temperature by 8.5°C. At night, the cooling side's sub-environmental temperature dropped by only 2.5°C, indicating effective suppression of overcooling. Overall, the film shows adaptive thermal management, achieving radiative cooling during the day and preventing excessive cooling at night, extending the material’s lifespan and reducing labor costs. A model cabin simulation shows that a cabin with a cooling layer maintains an average indoor temperature of 35.4°C under solar radiation exceeding 700 W m−2, compared to 44.3°C in an uncovered cabin. Conversely, a cabin with a heating layer reaches an indoor temperature of 59.2°C, significantly higher than the uncovered cabin, demonstrating the film's broad potential for energy savings in real-world applications.

Recyclability and Durability

The film can be systematically separated and extracted based on component solubility differences. First, soaking the film in hot acetone separates the carbon black component. The AC/EC solution in acetone is then introduced into water to precipitate AC/EC. The AC/EC powder is dissolved in hot ethanol, and the AC is extracted again through a dissolution-precipitation process. Recycled components can be reconstructed into new smart films with nearly unchanged appearance. Optical analysis of recycled samples shows a reflectance of 96.8% on the cooling side and an absorbance of 89.6% on the heating side, consistent with the original film's optical properties. The film also exhibits excellent weather resistance and anti-fouling properties. The cooling side has a water contact angle of 140°, and the heating side has a water contact angle of 120.5°, ensuring good hydrophobicity. Even after 30 days of exposure, the film's reflectance remains stable, highlighting its long-term durability. The film retains similar reflectance after 7 days of UV exposure, demonstrating its potential in addressing real-world environmental challenges.

Conclusion

This study successfully developed a recyclable multimodal smart film from fully biomass-based materials. The film enables adaptive day-night and year-round energy efficiency in buildings. In cooling mode, the film acts as a broadband radiator using the atmosphere for temperature regulation. With high broadband emissivity (95.4%) and solar reflectance (96.3%), it performs well with daytime cooling efficiency (8.5°C) and nighttime cooling (2.5°C). In heating mode, the film decorated with ultra-thin carbon black achieves high solar absorption (91.1%), ensuring excellent solar heating capability. The seamless transition between cooling and heating modes to adapt to seasonal changes is notable. Additionally, the film's recyclability provides a sustainable solution for building waste management. Its properties, including UV resistance, self-cleaning, and durability, enhance its practicality. This work represents a significant contribution to intelligent radiative thermal management, advancing next-generation sustainable building heat management.