Summary

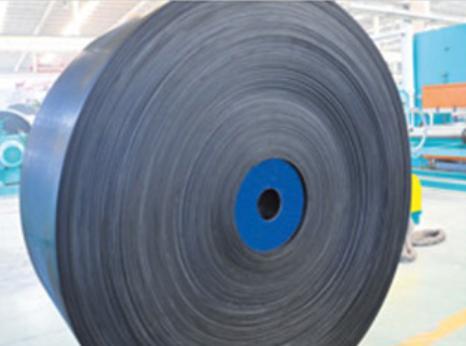

Heat-resistant belts and rubber additives ensure durability in harsh environments.

Summary

Heat-resistant belts and rubber additives ensure durability in harsh environments.

|

Raw materials

|

Basic formula

|

Raw materials

|

Basic formula

|

|

/Mass

|

/Mass

|

||

|

EPDM

|

100

|

Magnesium oxide

|

10

|

Zinc Oxide | 10 | Accelerator M | 2 |

Stearic acid | 1 | Accelerator TMTD | 2 |

Antioxidant IPPD&TMQ | 2 | Accelerator ZDC | 1.5 |